Offshore Gripper Arm

DF Barnes demonstrates excellence in fabricating and machining a 2.5-ton gripper arm, showcasing precision, resilience, and structural integrity for complex offshore projects.

Offshore Gripper Arm

- Fabrication and Machining of 2.5 ton gripper arm for offshore use.

- Major components machined from 12’ thick plate using the DF Barnes HAAS 1600-5 axis Horizontal Mill.

- 26 individual pieces were machined and subsequently assembled by shop crew.

- Once constructed specific components of the gripper arm was coated with Xylan, then the entire unit was coated for offshore use.

Location

St. John’s, NL

Client

Hyflodraulic

Scope

To Machine and Fabricate single gripper arm for offshore use

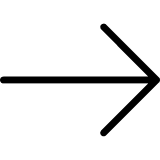

Whitefish Spillway Gate Refurbishment

Client: NL Hydro Division: Energy, RenewableDF Barnes refurbishes gate rollers, installs safety equipment, and conducts concrete remediation for a critical project.

West Aquarius Thruster Replacement & Rig Maintenance

Client: SeaDrill Division: Energy, Marine, ServicesDF Barnes removes and replaces thrusters for the West Aquarius and completes extensive maintenance work on the engines, hull and external systems of the rig.

Voisey’s Bay Mine Expansion

Client: Vale Division: Industrial, MiningVoisey's Bay Mine Expansion commissioning contract awarded to DF Barnes, encompassing construction, procurement, and supply chain management for project success.

Transocean Barents -Thruster Removal & Rig Maintenance

Client: Transocean Division: Energy, Marine, ServicesDF Barnes transports 75-ton thrusters, fabricates structures for the Transocean Barents, maintains engines and more.

Terra Nova FPSO Refit & Maintenance

Client: Suncor Division: Energy, Marine, ServicesDF Barnes rapidly provided Quayside Services and skilled personnel, amassing 350,000-man hours over five months with impeccable safety. Versatile support extended offshore for Suncor's reconnection endeavors.

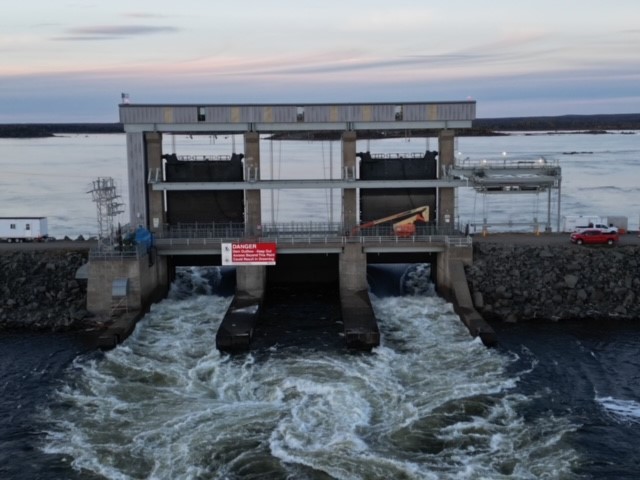

SeaRose Ballast Water Tank Repair

Client: Cenovus Division: Energy, Marine, ServicesDF Barnes showcased expertise in the SeaRose Ballast Water Tank repair. Quality processes ensured structural integrity and reliability.