Gas Lift Module

DF Barnes Fabricates gas lift module, showcasing teamwork, quality and safety.

Gas Lift Module

- Fabrication and Assembly of gas lift module for the Hibernia Platform.

- Fabrication of all structural components, in total measured 5 stories in height and weighed 135 tonnes.

- Trial assembly and perfection of component integration.

- Mobilization of unit to the Hibernia Platform.

- Installation of module on the Hibernia Platform.

Location

Argentia, NL

Client

ExxonMobile

Scope

Fabrication and construction of large gas lift module for installation on Hibernia Platform

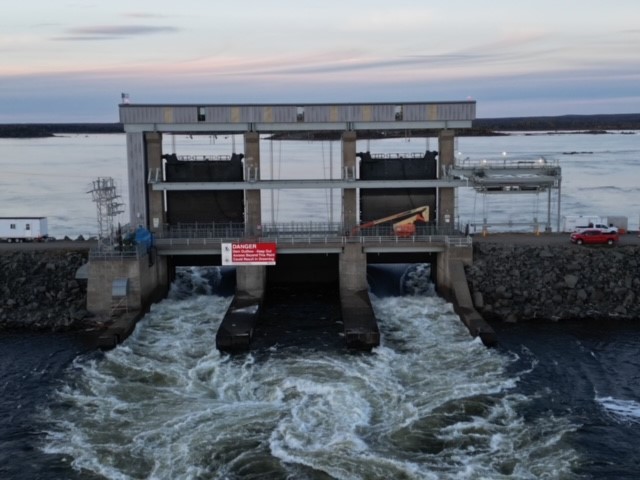

Whitefish Spillway Gate Refurbishment

Client: NL Hydro Division: Energy, RenewableDF Barnes refurbishes gate rollers, installs safety equipment, and conducts concrete remediation for a critical project.

West Aquarius Thruster Replacement & Rig Maintenance

Client: SeaDrill Division: Energy, Marine, ServicesDF Barnes removes and replaces thrusters for the West Aquarius and completes extensive maintenance work on the engines, hull and external systems of the rig.

Voisey’s Bay Mine Expansion

Client: Vale Division: Industrial, MiningVoisey's Bay Mine Expansion commissioning contract awarded to DF Barnes, encompassing construction, procurement, and supply chain management for project success.

Transocean Barents -Thruster Removal & Rig Maintenance

Client: Transocean Division: Energy, Marine, ServicesDF Barnes transports 75-ton thrusters, fabricates structures for the Transocean Barents, maintains engines and more.

Terra Nova FPSO Refit & Maintenance

Client: Suncor Division: Energy, Marine, ServicesDF Barnes rapidly provided Quayside Services and skilled personnel, amassing 350,000-man hours over five months with impeccable safety. Versatile support extended offshore for Suncor's reconnection endeavors.

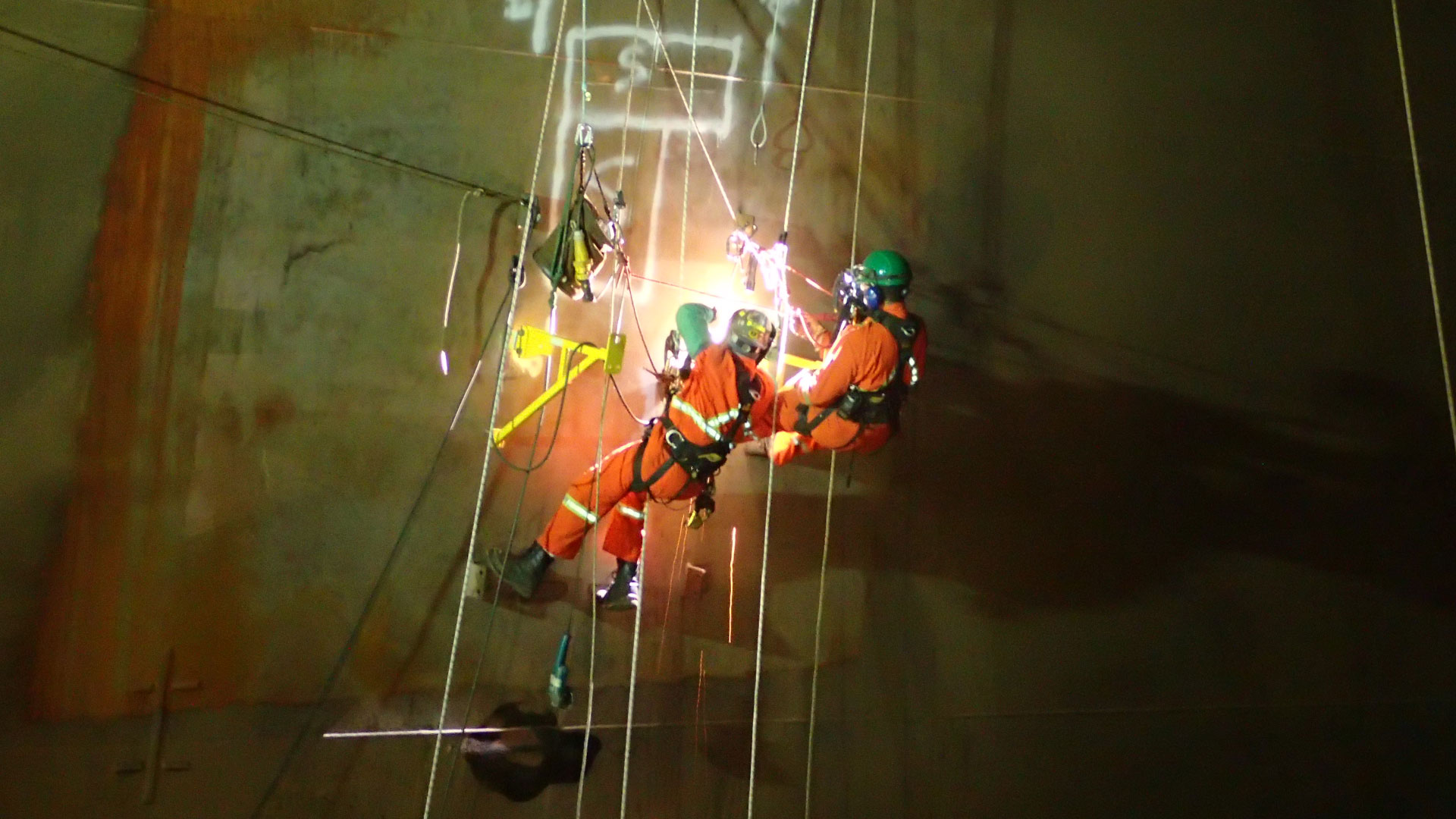

SeaRose Ballast Water Tank Repair

Client: Cenovus Division: Energy, Marine, ServicesDF Barnes showcased expertise in the SeaRose Ballast Water Tank repair. Quality processes ensured structural integrity and reliability.